Wow… 2 posts in the past week! I’m on a roll!! It’s Tuesday and I have a little time between homework checking and getting the eldest child off to soccer practice. I get asked on a weekly basis “I am looking to buy an embroidery machine. Which would you recommend?” While I would have thought I had posted this helpful info before, I couldn’t find much when I searched in my blog. When asked this question, my answer is usually “look at the Brother PE770”. Let me say this… there are LOTS and LOTS of different beginner embroidery machines out there. You can find single needle machines from Brother, Bernina, Singer, etc. I only recommend the PE770 because that is what I (and so many others) started with. Mine was actually a PE700 model but that’s just an older model number. Of course it has been several years since I have had it, so I can’t tell you how to adjust the tension or even thread the thing. However, if you google it, you can find plenty of info out there. I got my first one via E-bay from Ken’s Sewing Center in Muscle Shoals, AL. They shipped it to me and I taught myself how to use it. I got my second one (PE780D I think ~ Disney version) from Ken’s also and again, they shipped it right to me. Here is a link to this machine on their website and there is a video demo you can watch if you are interested.

I couldn’t find a photo of my old machine (although I KNOW I have some somewhere) so here is a stock photo! Again, I taught myself how to use it with very little sewing experience.

Here are a few features:

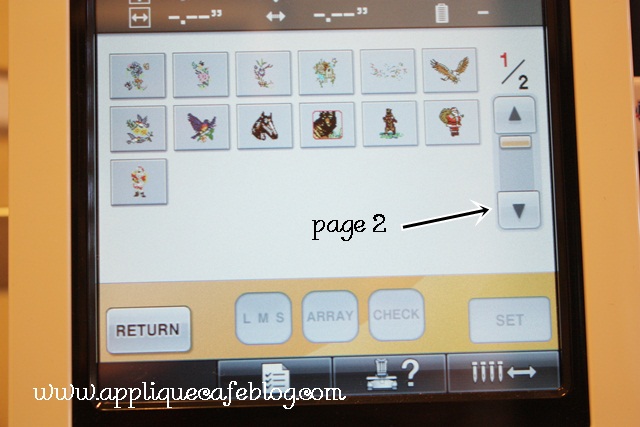

- 136 built in embroidery designs (I never used any of these)

- 6 embroidery alphanumeric fonts (you MAY want additional font software)

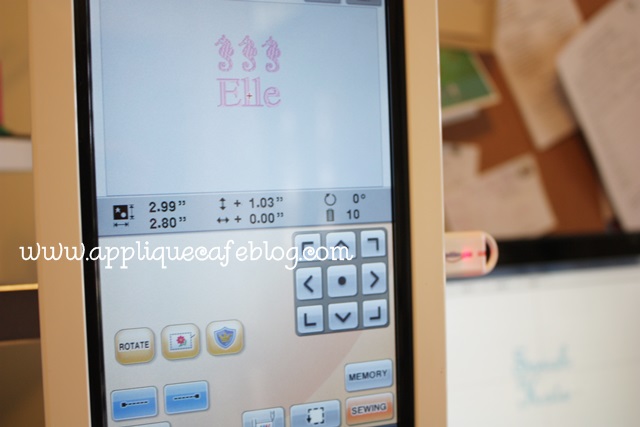

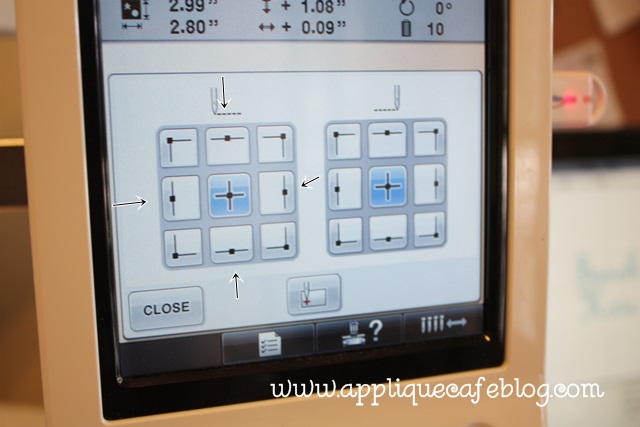

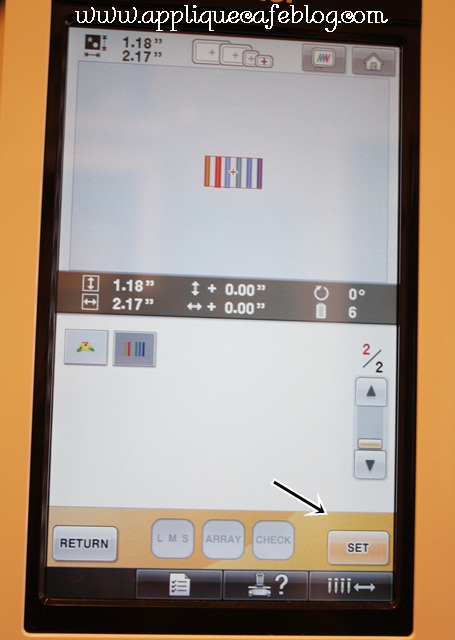

- Patterns can be rotated in 1, 10 or 90 degree increments

- 10 built in frame shapes and 12 border styles

- Maximum embroidery field of 5″ x 7″ (I believe the machines comes with a 5×7 hoop only)

- Expand to 12″ x 5″ with optional multi-position embroidery frame

- Embroidery speeds up to 650 spm (my 6 needle stitches 1,000 SPM)

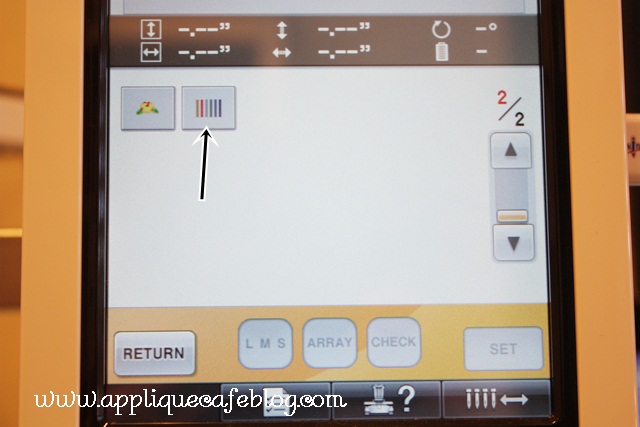

- Easily import designs from your USB memory stick (you will use a thumb drive ~ save files to it from your computer, then put the memory stick in to the machine to sew)

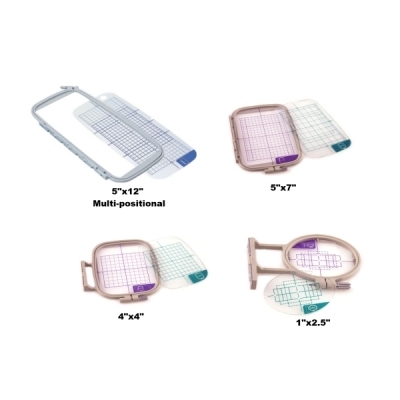

Here are the different hoop sizes. The machine comes with a 5″ x 7″ hoop which is plenty big for most projects. You can also purchase the 4″ x 4″ and the 2″ x 3″ hoops. You will use the 4×4 hoop for smaller projects (think onesies, baby gowns, etc.). I don’t recall using the 2×3 much. On this note, there are also Brother SE model machines out there and the max hoop you can use is 4×4. Most people learn quickly that 4×4 is not big enough for a long term machine and quickly want to upgrade to at least 5×7. If you can spend the extra money, get a machine with at least a 5×7 hoop. There is also a 5 x 12 multi positional hoop you can purchase, but I never got this hoop nor do I understand how to use it. You would need to talk to a sewing center about how to use it and if it would work for you.

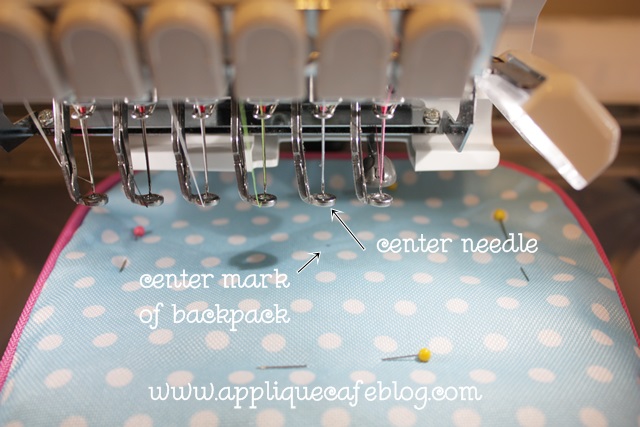

I used my PE machines for about 3 years and did everything I wanted to do on them. There is a huge jump in price from most single needle machines (w/ 5×7 hoops) to larger hoop machines. To fit an applique design and a name, for example, you can always hoop twice! {Stitch the design, then rehoop and add the name}

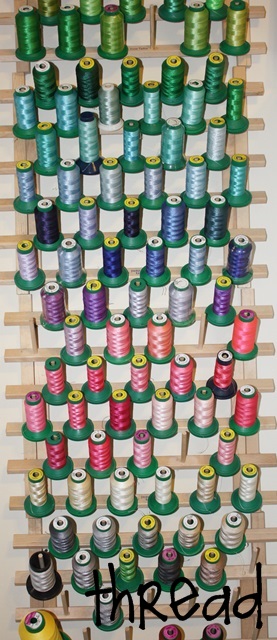

What else will you need? Embroidery thread is a must. I use Isacord and Exquisite brands 98% of the time. Both are 100% polyester. You can get Exquisite from Ken’s Sewing Center and Isacord from Sewingmachine.com. Both should sell actual thread charts (with real thread samples) which makes ordering online easier.

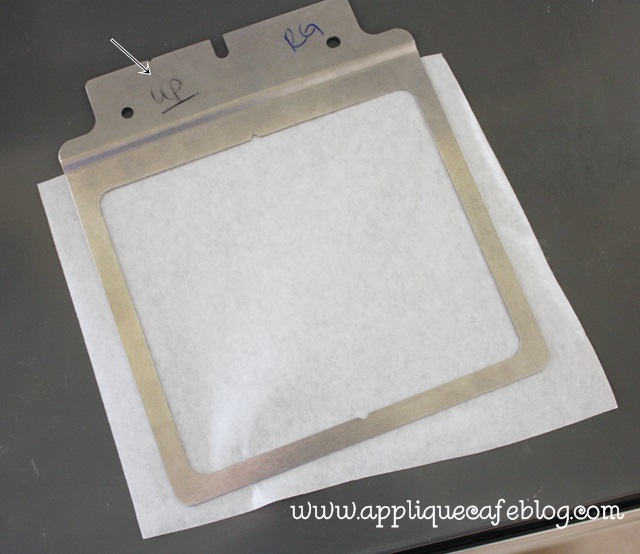

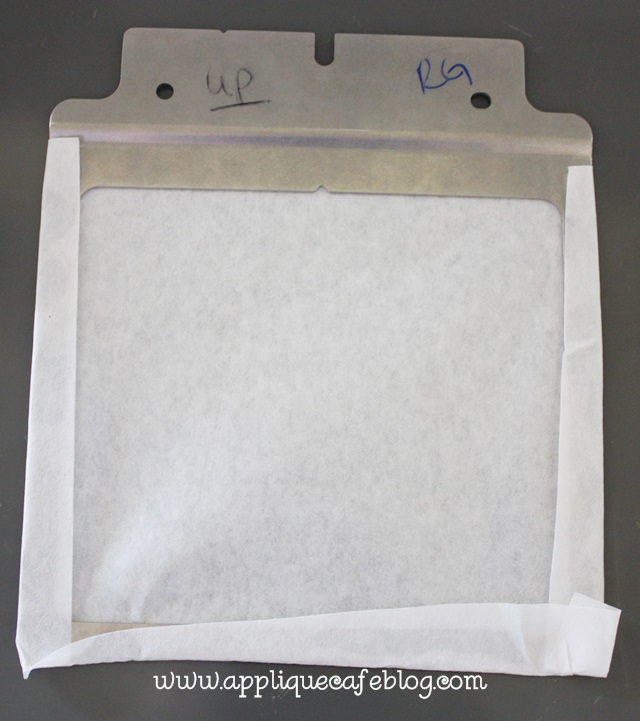

You will also need stabilizers. You can find more posts on stabilizer under Helpful Posts. Stabilizer supports your garment or item when stitching designs (embroidery {all thread} or applique {fabric}).

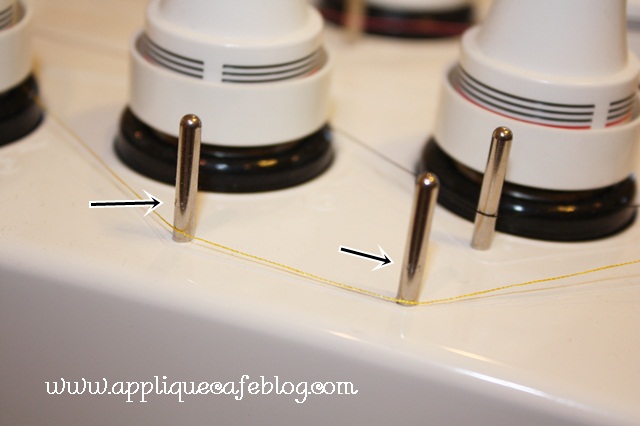

Bobbins are needed too. There is a certain type bobbin that fits each embroidery machine, so you will need to find out from your sewing center (or wherever you buy your machine or supplies) which bobbins to get. I like PREWOUND bobbins. Below are magnetic bobbins I use in my PR650 6-needle machine. Most single needle machines use regular prewound bobbins (not magnetic). You can also wind your own, but prewound are easier and the tension is more consistent!

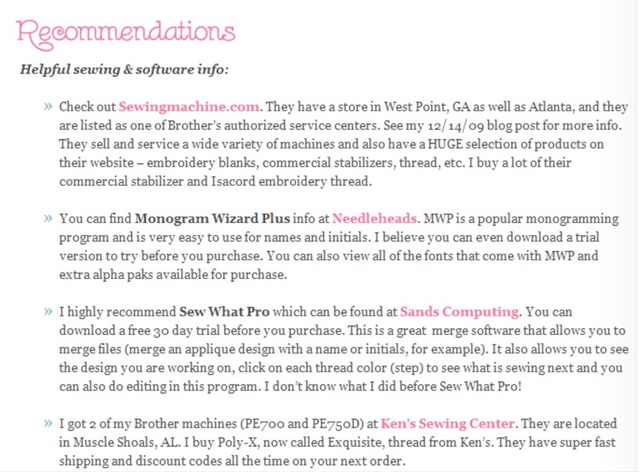

Of course there are other things you will need like scissors, fabric for applique, etc. Hopefully if you are in the market for a machine, this will get you started! Here are RECOMMENDATIONS on my blog for the software I use and where I got it. Again, there is lots of software out there but these are the ones I use and like!

Lastly, you may have noticed a new ad button on my sidebar! Some good friends of mine own an awesome home & garden center here in Montgomery (AL) and they are working on expanding their website. If you are in the SOUTH then you may have heard of Southern Homes & Gardens (or you may have been to their store). They also advertise in Southern Living quite often. We are working on a giveaway on Facebook for SH&G, but in the meantime check out their online store!

Have a great week! We are working on new designs for Applique Cafe such as this one…

Recent Comments