HAPPY NEW YEAR my faithful blog readers!! It’s a NEW YEAR and I’ve got some new 2017 SQUAD GOALS!!!!

- MORE BLOG POSTS!!! If you evveerrrr have a suggestion, please let me know! After all these years it’s hard to come up with new material. Jeff says he is going to help in this department as well. I would even welcome guest posts! Do you like embroidery related? What we are up to? What do you want to read?

- With more blog posts I promise to actually read and approve and answer comments in a more timely fashion! 🙂

- MORE newsletters. I actually pay good money to send you newsletters, and some months I don’t even send them. Basically it’s like giving money to my newsletter provider for doing nothing. So, I hope to send out a newsletter a month with sale info, new design info, new blog posts, etc.

- MORE designs. We get so busy and weeks fly by. We hope to do more designs and on a more regular basis.

I’m sure the list will grow! We’ve been doing this since 2009 and we want to stay strong and continue providing you with great simple and unique designs and help you out on the blog along the way!

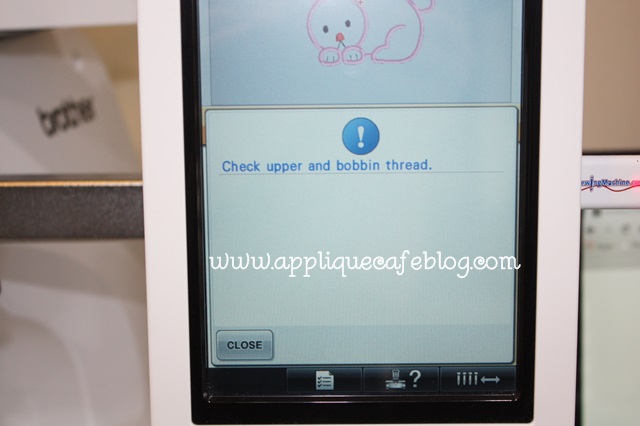

On that note, it’s a NEW YEAR, and a great time to CLEAN YOUR MACHINE!! Now would be the perfect time to get your machine in shape for the new year, and also set a schedule to keep it clean and maintained. Set a reminder on your phone. Mark your calendar. Get on a schedule!! The schedule really depends on your machine usage, but you need to keep your machine clean and free of lint and junk and also CHANGE YOUR NEEDLES on a regular basis. Are you using more sticky stabilizer than usual? Are you doing more towels and linty stuff than usual? If so, you need to clean it more often! I did mine this morning…

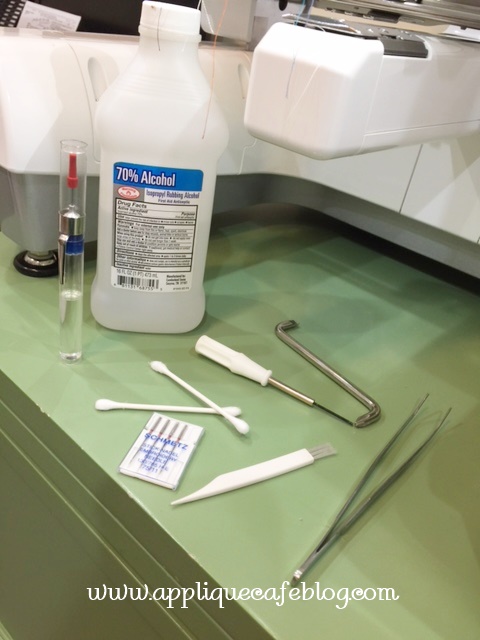

Here are the tools needed. If you have a multi needle, they came with your machine. I also use alcohol and Q-tips to get the gunk! I’m a couple of needles short to change out my 6, so heading to Joann at some point today so I can change them all. I use Schmetz 75/11 Embroidery Needles.

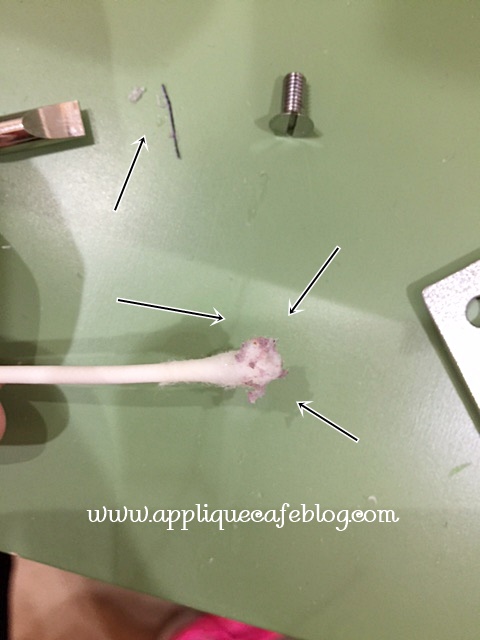

Here is some of the gunk that came out of my bobbin case area. GROSS!

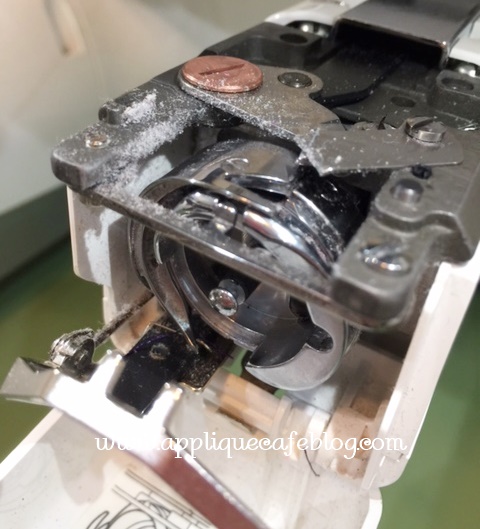

I use the brush as well as the alcohol+Q-tips to clean the bobbin case area really well. I also dust around where the needles are screwed in, and dust the top of the machine where the tension knobs are. You just need to make sure to get the dust away from the machine, and not blow it IN to your machine.

It’s amazing the amount of dust that can accumulate! I did my share of towels for Christmas, so keep in mind the projects you are working on. If you are doing a lot of towels, or using sticky stabilizer a lot, then you need to clean and change needles more often.

Take the plate off the bobbin case area to really get inside the bobbin case. When all clean, screw it back on tightly.

For a complete blog post on Multi Needle Machine Maintenance, check out my previous blog post by clicking HERE. It has been shared and pinned a lot on Pinterest!

Happy 2017 to you and you’ll be hearing from me again soon!

Rosemary

Recent Comments