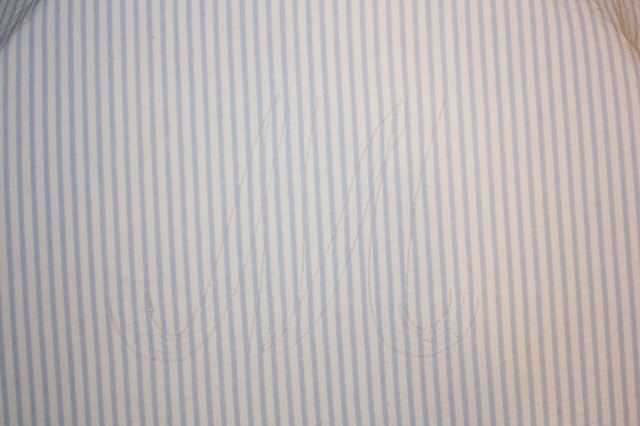

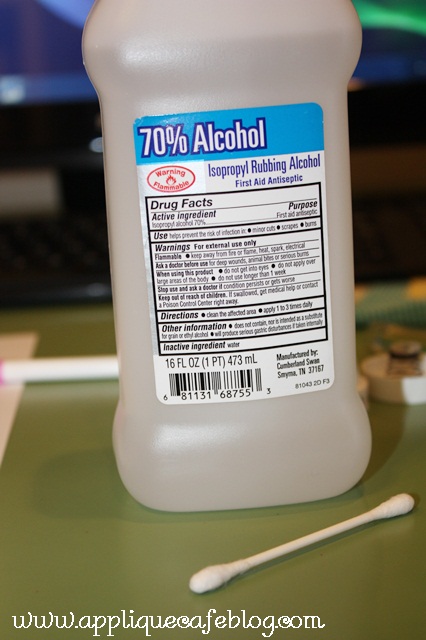

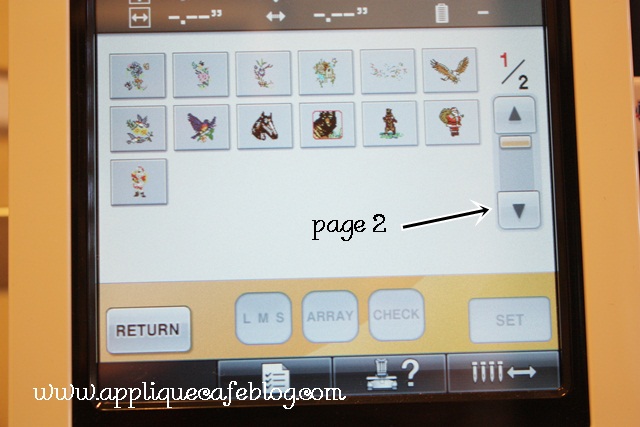

Happy post-Easter (and post-Spring Break for us)!! It feels like I was JUST picking out school supplies, and here we are past Easter with 7 or so weeks away from school being out for SUMMER. Of course today I have on jeans, rain boots and 2 long sleeve layers up top b/c it’s 54 degrees and dreary outside. Doesn’t feel like spring, but it’ll be here before we know it (and I will be complaining because I’m sweating to death). I heard via Facebook recently that someone who’s “work” I admire used a different kind of stabilizer than I use for t-shirts. I have heard of this stabilizer before but I really didn’t know what it was like or if I would like it. So, I decided to order me some and try it out. I used it for the first time yesterday and I liked it, but the verdict is still out. It’s Lightweight Cutaway No Show Mesh from Sewingmachine.com. It’s hard to tell from their photo what it looks like, so here is another pic for you…

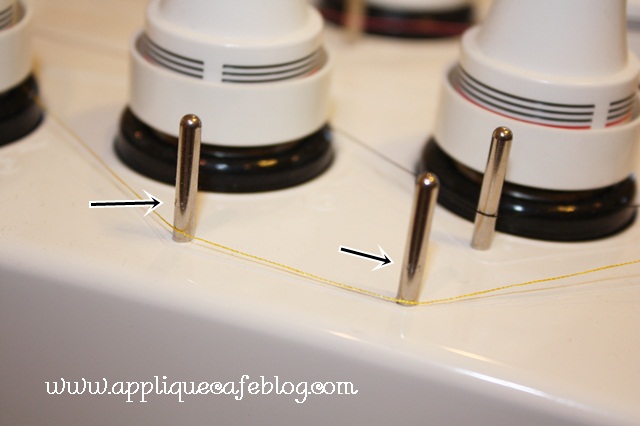

It turns out I had something LIKE this that I’ve used before, mostly on sweatshirts. The friend who recommended this also said she “floats” a piece of tearaway underneath which I forgot to do, but I still got good results. Here is a pic of it on the inside of my shirt. I used it like I use any cutaway and “stuck” it to the shirt with my Sulky KK2000 temporary spray adhesive before I get it hooped.

Here is the finished shirt, and it looks like any other applique I have done. I will say… the brown gingham dog fabric was a little “bubblier” than I find when using my medium cutaway, but I was able to squirt some water on it with my iron and iron it really well and the Heat N Bond Lite worked and it turned out just fine. So… not sure I am making a drastic switch over to this new cutaway, but I did like it and will try it again (and try floating tearaway underneath for a little added support). I think the idea of this “no show mesh” is that it’s a lot thinner than medium cutaway so it doesn’t “show” on the shirt, which I don’t have a problem with. Some people say you can see the stabilizer around the design, but I’ve been using it for years and have never had anyone complain nor has it ever bothered me. But, if that is something that concerns you then you might give this a try!

The moral of the story… try new things! You have to figure out what works best for you! Just because I use and love medium cutaway (which I am completely out of BTW…) doesn’t mean you have to! I have a whole roll of this no show mesh, so I will try it some more for sure!

I always LOOOOVVVEEEEEE…. opening a box from my doorstep from TJ’s Fabrics! A funny side story… when we got home around 2:20 from all the running around and carpools, we noticed the doorbell was ringing. It kept ringing, and ringing, and ringing. I ran to the front door to see who was there, and all I found was the TJ’s package! Evidently the mail-person left it for me and rang the doorbell. The doorbell got stuck and rang and rang and rang until we got home! Good thing we don’t have a dog or else it might have gone crazy!!

Now on to fabric… I saw these “mini” chevrons the other day on TJ’s Facebook page and knew I had to have some! I always tell people that in applique, you are dealing with such tiny spaces so small prints are GREAT! The top left one looks PERFECT for patriotic designs. Top right – great spring colors – lime, turq., yellow, orange. The bottom one is a few shades of pink and lime/green. LOVE LOVE LOVE!! Great job Timeless Treasures!! These are “mini chevron stripe”.

Love these 2 together ~ Timeless Treasures Small Geometric Multi on the right. Fun colors for summer!

Here are some new Riley Blake chevrons in some great new colors! A-D-O-R-E the lime green. Top left is purple, then orange, lime, blue and baby pink. I really like this lime and blue color!

These 2 look great together too!

More chevrons ~ these are also Riley Blake. The top left one would be great for Auburn fans! This group is called “One for the Boys” and I love all of the colors!

I think if I didn’t get to designs appliques, I would love to design fabric!! All of these make me want to sew something! How about you? Check them all out at TJ’s Fabrics!

Recent Comments